HR-TC220

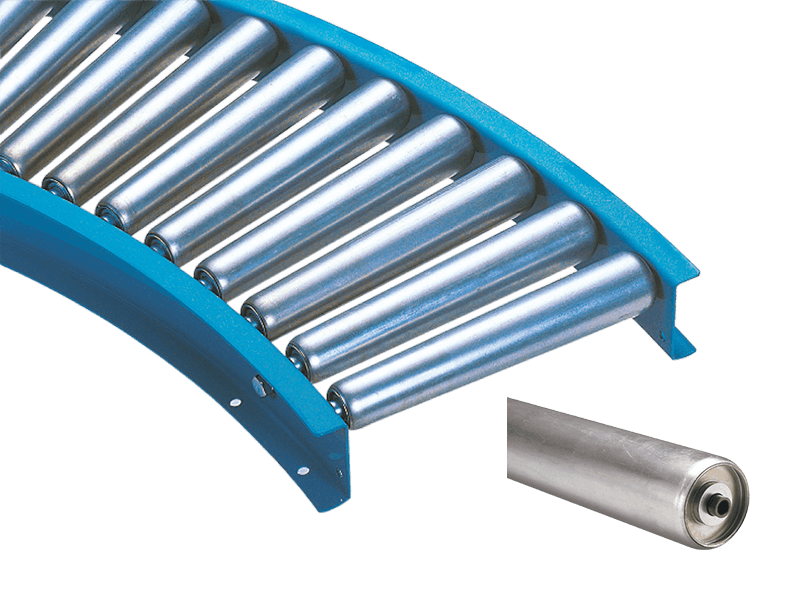

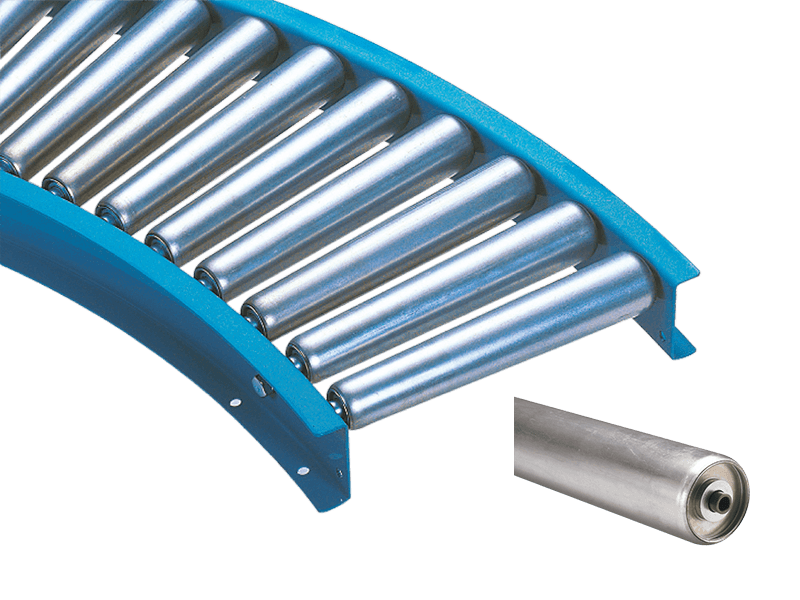

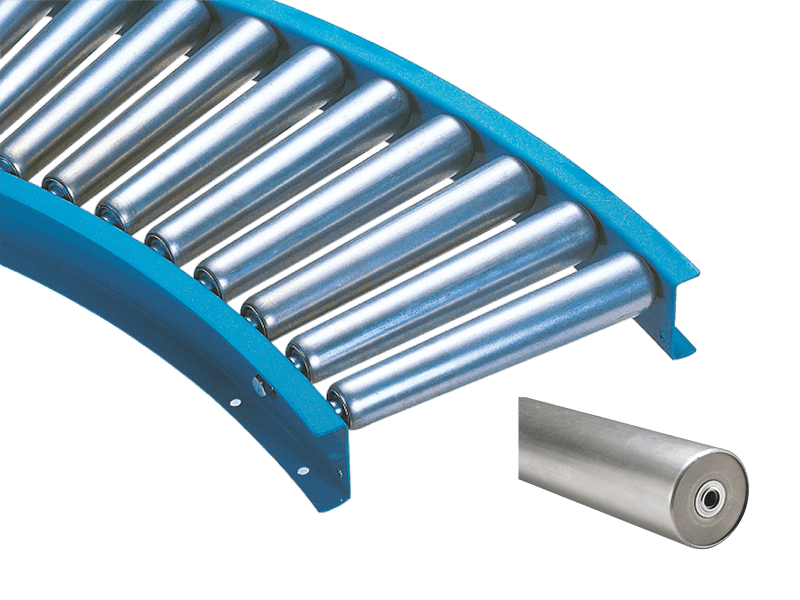

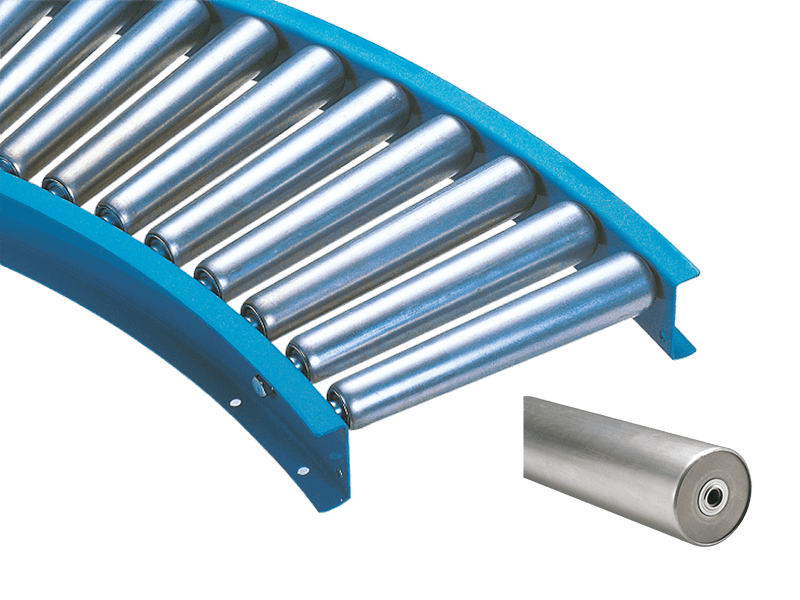

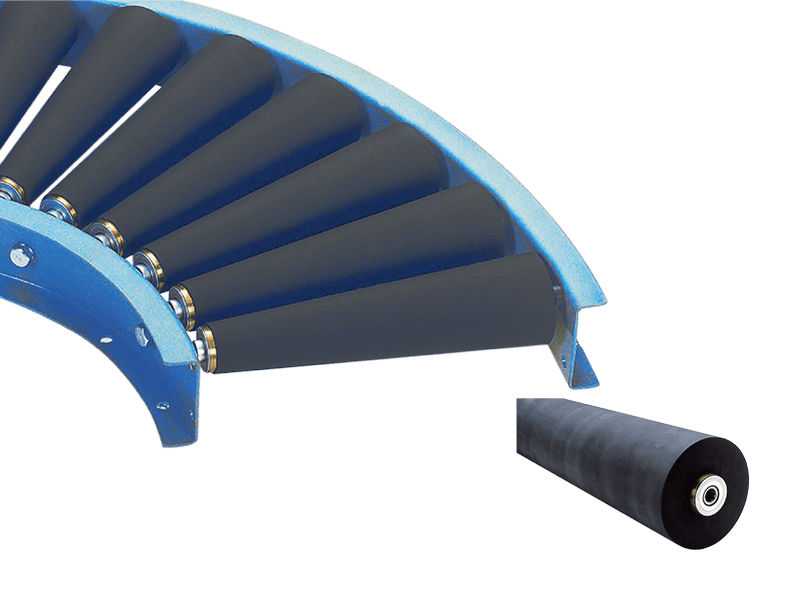

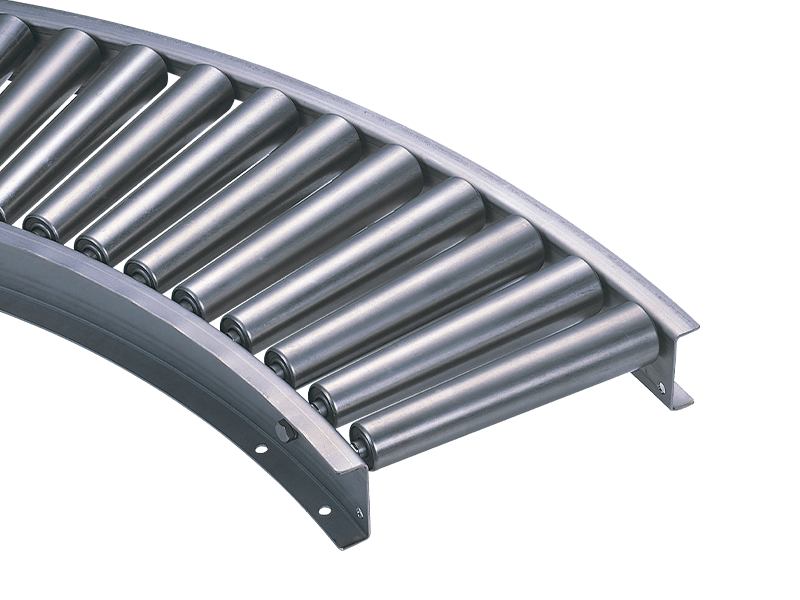

Cat:Penghantar roller tirus

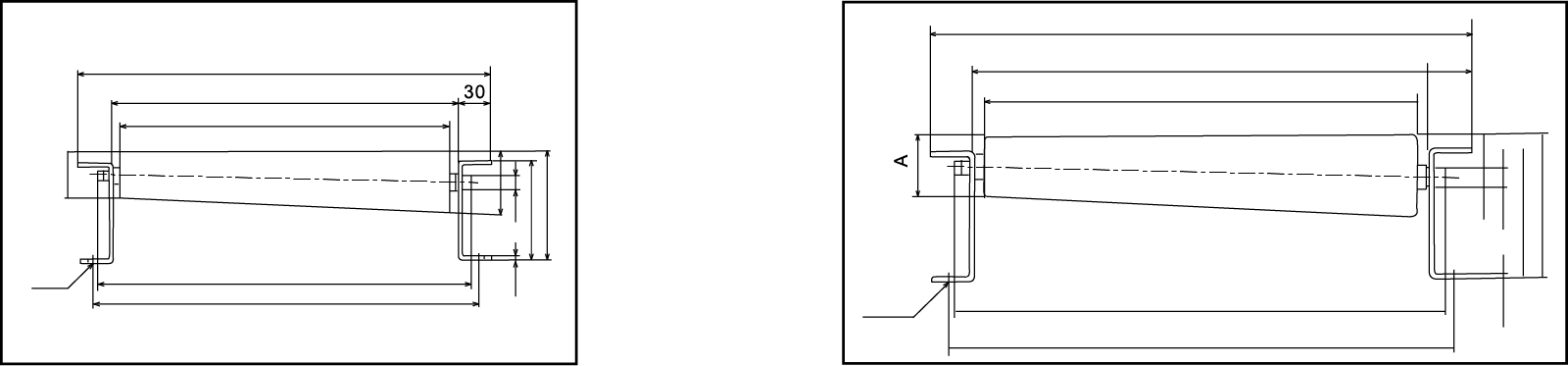

Lebar w (mm) 200 A (φ) Diameter 31.3 ...

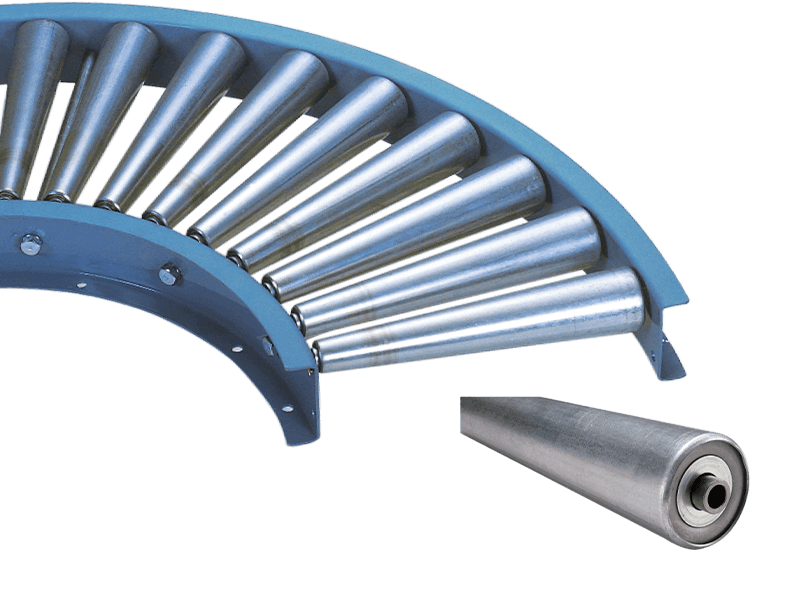

Struktur lanjutan, prestasi berkualiti tinggi, mudah digunakan, kebolehpercayaan dan ketahanan yang tinggi.

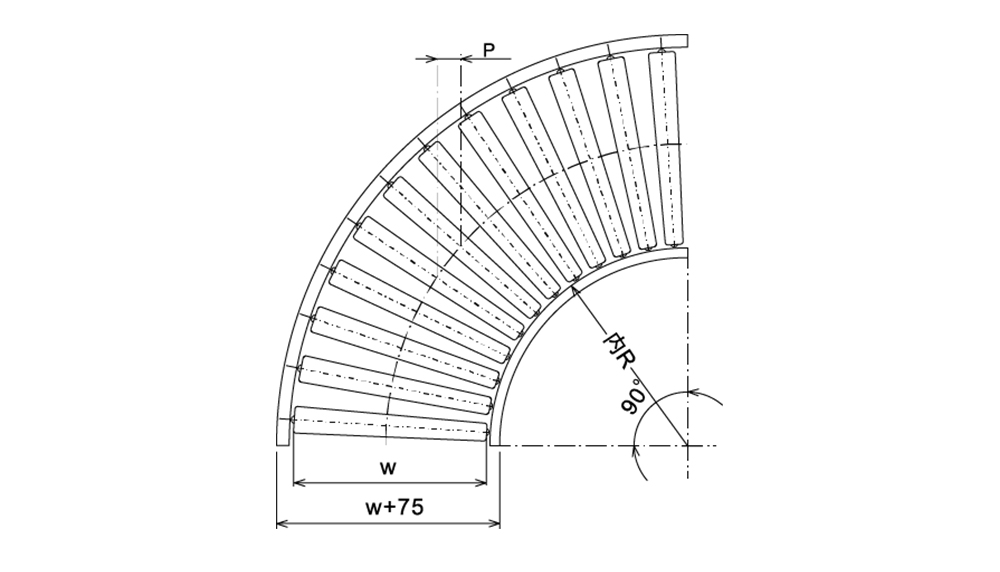

Juga dikenali sebagai penghantar roller lengkung, penghantar roller tirus membolehkan sudut bertukar 30, 45, 60, 90, dan 180 darjah. Ia digunakan terutamanya untuk perubahan arah dalam garisan penghantar, dengan 30, 45, dan 60 darjah sering digunakan untuk cawangan dan penggabungan penghantar. Penghantar ini adalah jenis ringan dengan kapasiti beban umumnya tidak melebihi 200 kg.

| R | Jenis \ lebar | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 | Padang roller |

| 220 | HR-TC220 | ○ | - | - | - | - | - | - | - | - | - | - | 50,75,100 |

| 320 | HR-TC320 | - | ○ | - | - | - | - | - | - | - | - | - | 50,75,100 |

| 500 | HR-TC500A | - | ○ | ○ | ○ | ○ | ○ | - | - | - | - | - | 75 |

| 700 | HR-TC700 | ○ | ○ | ○ | ○ | ○ | - | - | - | - | - | - | 75,100,150 |

| 900 | HR-TCN | - | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | - | 75,100,150 |

| HR-TC900 | ○ | ○ | ○ | ○ | ○ | - | - | - | - | - | - | 75,100,150 | |

| HR-TC900A | - | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | - | 75,100 | |

| HR-TCL | - | - | - | - | - | - | - | ○ | ○ | ○ | ○ | 75,100,150,200 | |

| 1200 | HR-TC1200 | ○ | ○ | ○ | ○ | ○ | - | - | - | - | - | - | 75,100,150 |

| HR-TC1200A | - | - | - | - | - | - | ○ | ○ | ○ | ○ | ○ | 75.100 | |

| 1600 | HR-TC1600 | - | - | ○ | ○ | ○ | ○ | ○ | - | - | - | - | 75,100,150,200 |

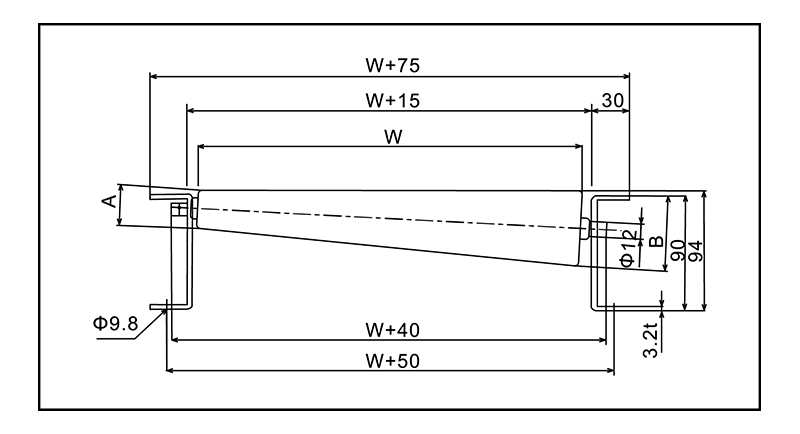

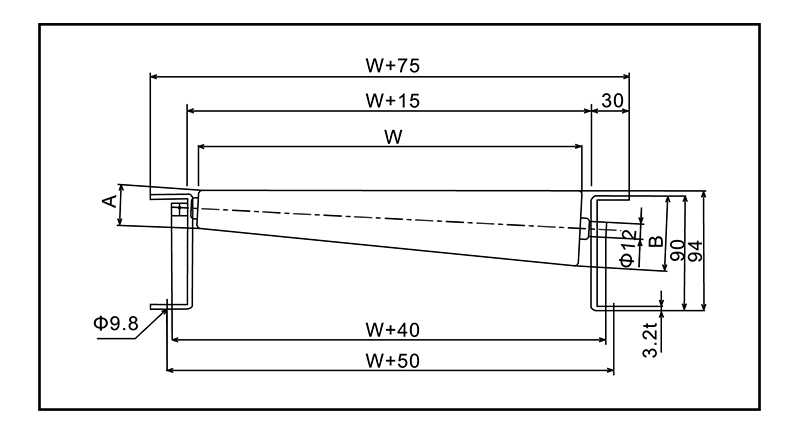

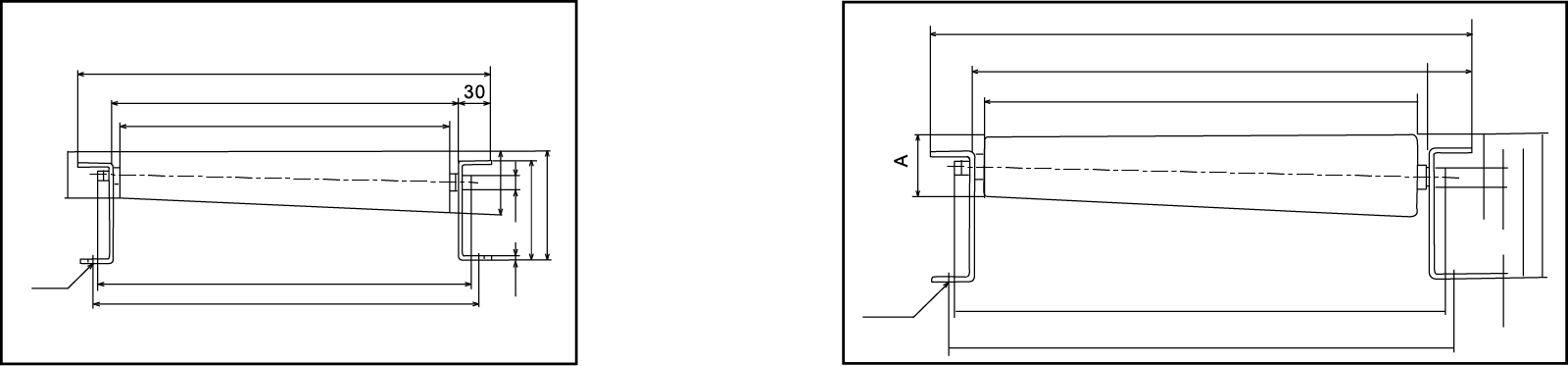

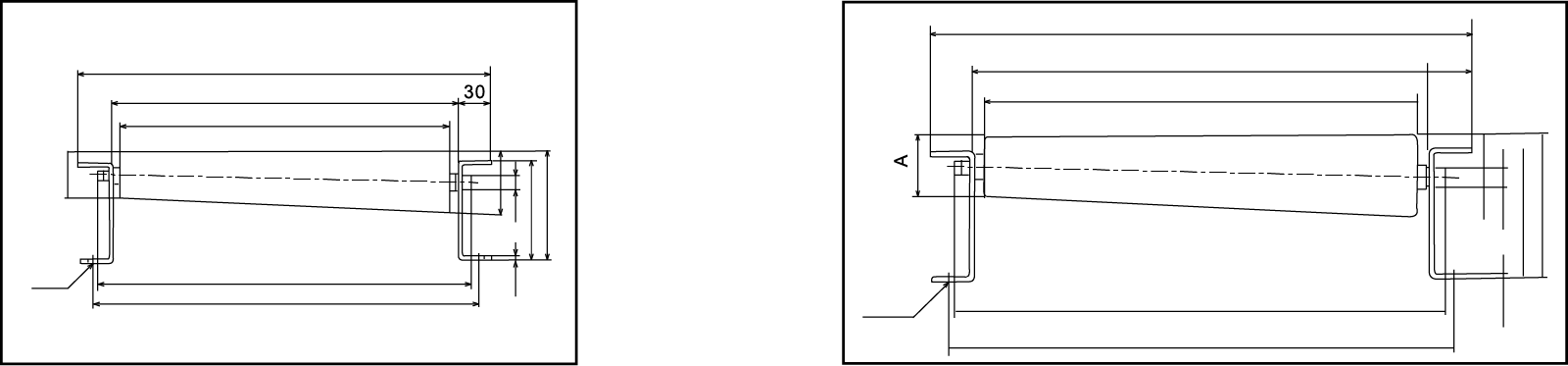

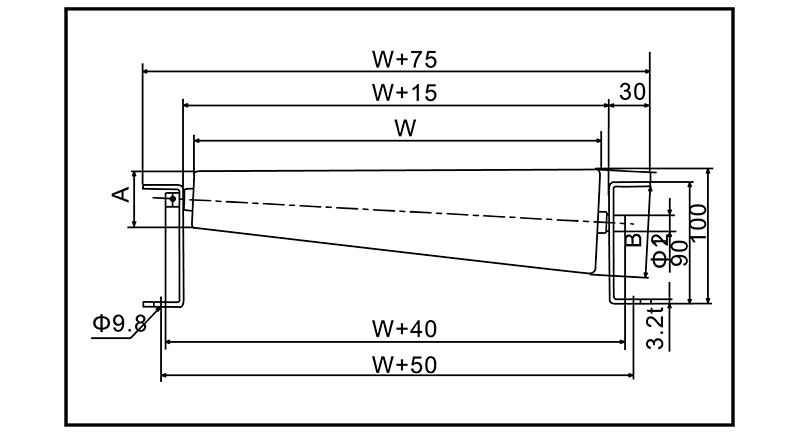

Lebar w (mm) 200 A (φ) Diameter 31.3 ...

| Lebar w (mm) | 200 | |

| A (φ) | Diameter | 31.3 |

| Ketebalan | 3.5 | |

| B (φ) | Diameter | 60.5 |

| Ketebalan | 2.0 | |

| Memuatkan roller (kg) | 100 | |

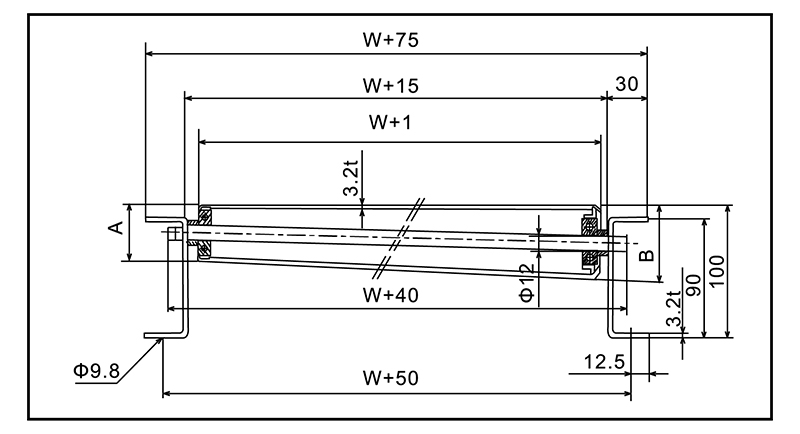

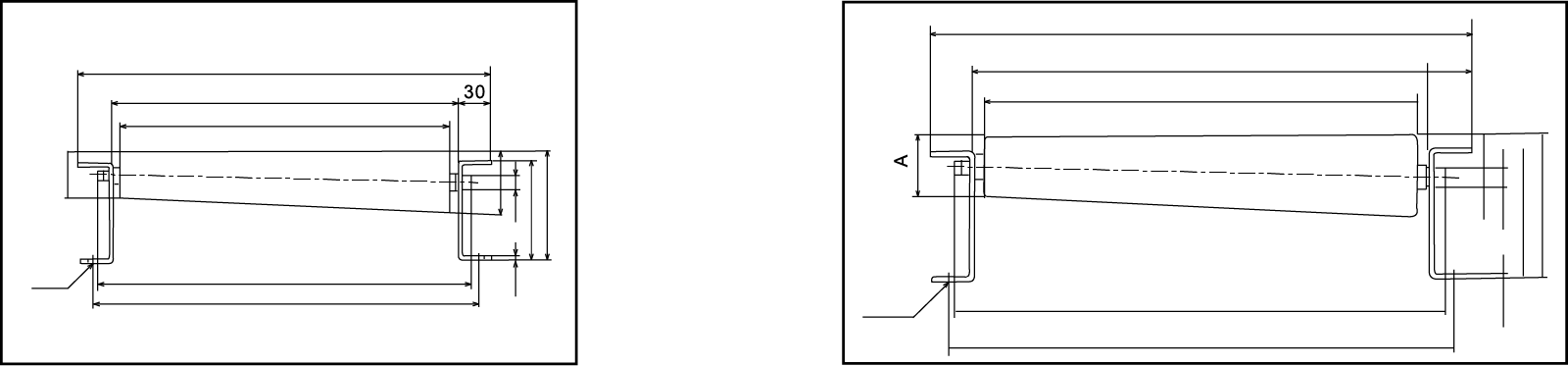

Lebar w (mm) 300 A (φ) Diameter 31.2 ...

| Lebar w (mm) | 300 | |

| A (φ) | Diameter | 31.2 |

| Ketebalan | 3.6 | |

| B (φ) | Diameter | 60.5 |

| Ketebalan | 2.1 | |

| Memuatkan roller (kg) | 100 | |

Lebar w (mm) 300 400 500 600 700...

| Lebar w (mm) | 300 | 400 | 500 | 600 | 700 | 800 | |

| A (φ) | Diameter | 42.7 | 42.7 | 42.7 | 42.7 | 42.7 | 42.7 |

| Ketebalan | 3.2 | 3.2 | 3.1 | 3.1 | 3.1 | 3.1 | |

| B (φ) | Diameter | 56.8 | 61.3 | 66.4 | 71.3 | 76.2 | 80.0 |

| Ketebalan | 2.1 | 2.1 | 2.1 | 2.1 | 2.0 | 2.0 | |

| Memuatkan roller (kg) | 100 | 90 | 85 | 76 | 59 | 54 | |

Lebar w (mm) 900 1000 1100 1200 ...

| Lebar w (mm) | 900 | 1000 | 1100 | 1200 | |

| A (φ) | Diameter | 42.7 | 42.7 | 42.7 | 42.7 |

| Ketebalan | 3.5 | 3.8 | 4.5 | 4.5 | |

| B (φ) | Diameter | 86.7 | 91.0 | 95.3 | 100.0 |

| Ketebalan | 2.0 | 1.8 | 2.0 | 1.8 | |

| Memuatkan roller (kg) | 110 | 95 | 87 | 80 | |

Lebar w (mm) 200 300 400 500 600...

| Lebar w (mm) | 200 | 300 | 400 | 500 | 600 | |

| A (φ) | Diameter | 41.3 | 41.3 | 41.3 | 41.3 | 41.3 |

| Ketebalan | 3.3 | 3.3 | 3.3 | 3.3 | 3.3 | |

| B (φ) | Diameter | 52.2 | 57.6 | 63.1 | 68.6 | 74.0 |

| Ketebalan | 2.5 | 2.4 | 2.4 | 2.3 | 2.3 | |

Lebar w (mm) 200 300 400 500 600...

| Lebar w (mm) | 200 | 300 | 400 | 500 | 600 | |

| A (φ) | Diameter | 45.0 | 45.0 | 45.0 | 45.0 | 45.0 |

| Ketebalan | 3.2 | 3.2 | 3.2 | 3.2 | 3.2 | |

| B (φ) | Diameter | 54.9 | 59.9 | 64.9 | 69.8 | 74.8 |

| Ketebalan | 2.2 | 2.2 | 2.1 | 2.1 | 2.0 | |

Lebar w (mm) 200 300 400 500 600...

| Lebar w (mm) | 200 | 300 | 400 | 500 | 600 | |

| A (φ) | Diameter | 48.0 | 48.0 | 48.0 | 48.0 | 48.0 |

| Ketebalan | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | |

| B (φ) | Diameter | 56.8 | 61.2 | 65.7 | 70.1 | 74.5 |

| Ketebalan | 2.3 | 2.3 | 2.2 | 2.2 | 2.1 | |

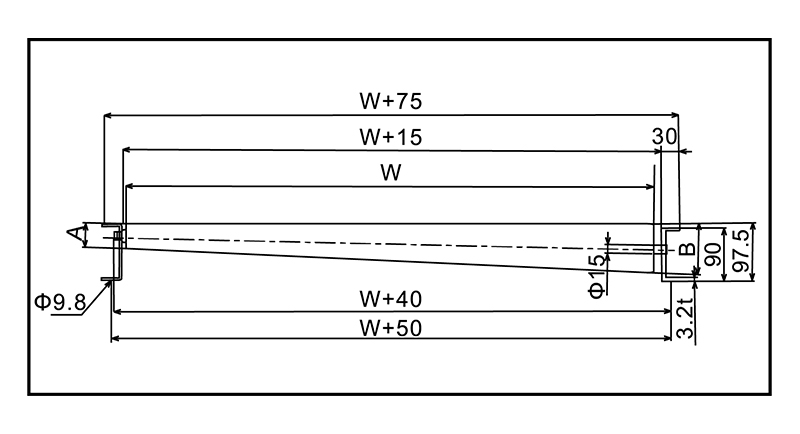

Lebar w (mm) 400 500 600 700 800...

| Lebar w (mm) | 400 | 500 | 600 | 700 | 800 | |

| A (φ) | Diameter | 50.0 | 50.0 | 50.0 | 50.0 | 50.0 |

| Ketebalan | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | |

| B (φ) | Diameter | 63.0 | 66.3 | 69.5 | 72.8 | 76.0 |

| Ketebalan | 2.3 | 2.2 | 2.2 | 2.1 | 2.0 | |

Lebar w (mm) 300 400 500 600 700...

| Lebar w (mm) | 300 | 400 | 500 | 600 | 700 | 800 | |

| A (φ) | Diameter | 42 | 42 | 42 | 42 | 42 | 42 |

| Ketebalan | 2 | 2 | 2 | 2 | 2 | 2 | |

| B (φ) | Diameter | 79 | 91 | 103 | 116 | 128 | 140 |

| Ketebalan | 20.5 | 26.5 | 32.5 | 39.0 | 45.0 | 51.0 | |

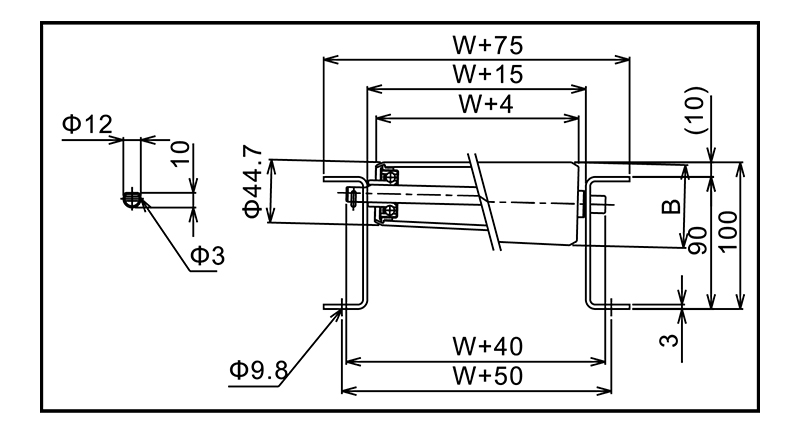

Lebar w (mm) 200 300 400 500 600...

| Lebar w (mm) | 200 | 300 | 400 | 500 | 600 | 700 | |

| A (φ) | Diameter | 44.7 | 44.7 | 44.7 | 44.7 | 44.7 | 44.7 |

| Ketebalan | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | |

| B (φ) | Diameter | 54.6 | 59.6 | 64.5 | 69.5 | 74.4 | 75 |

| Ketebalan | 2.4 | 2.3 | 2.3 | 2.2 | 2.2 | 2.2 | |

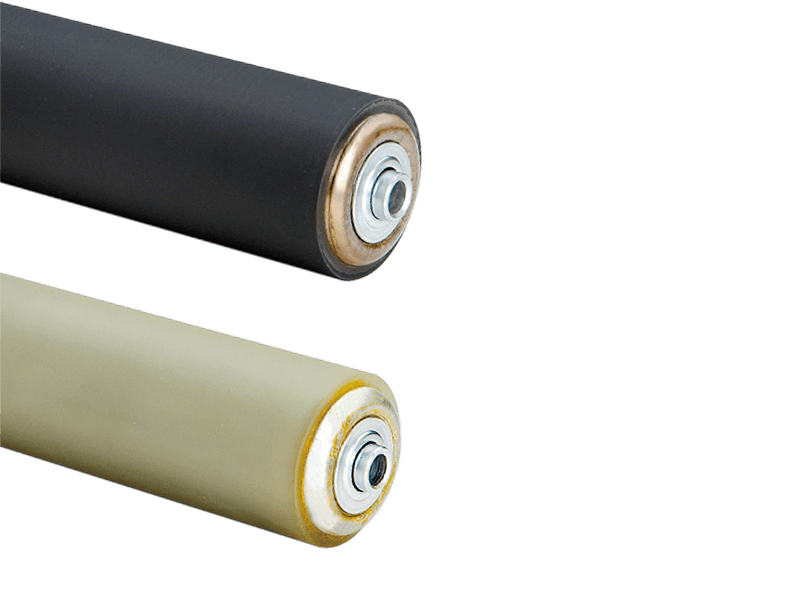

Jenis Tanda Ketegaran Rintangan haba Rintang...

| Jenis | Tanda | Ketegaran | Rintangan haba | Rintangan sejuk | Rintangan minyak | Pakai rintangan | |||

| Getah asli | Nr | Kira -kira 60 | 120C | -50 ° ℃ | X | O | |||

| Ding Nitrile Rubber | Nbr | Kira -kira 60 | 130C ° | -10 ° C. | O | O | |||

| Getah poliuretana | Pu | Kira -kira 90 | 80C ° | -30 ° C. | O | O | |||

| Getah asli | Ding Nitrile Rubber | Roller | Diameter*ketebalan*diameter paksi | Lebar roller | |||||

| RR-4812p | RRG-4812P | R-3812p | 48*5*12 | 100 ~ 1500 | |||||

| RR-4816 | RRG-4816 | R-3816 | 48*5*12 | 100 ~ 1500 | |||||

| RR-6721P | RRG-6721P | R-5721P | 67*5*12 | 100 ~ 1500 | |||||

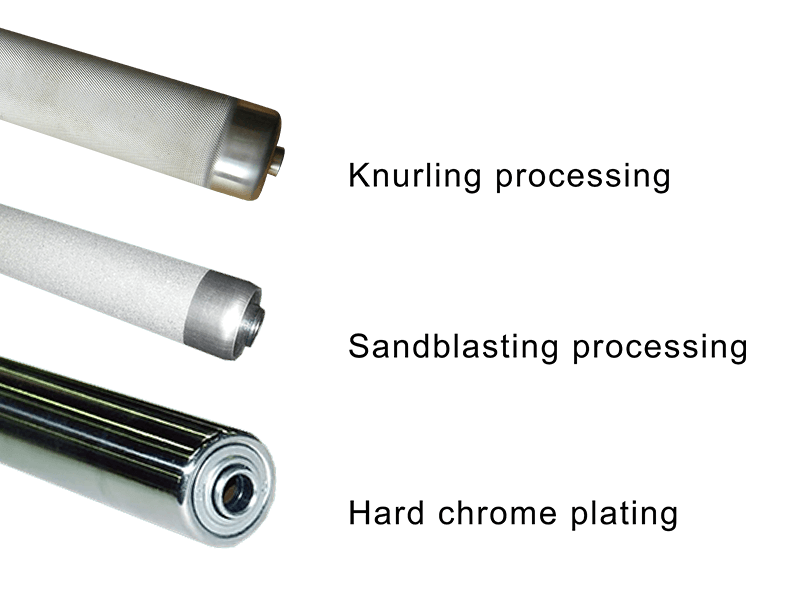

Jenis penyaduran Kelebihan Ketebalan penyaduran El...

| Jenis penyaduran | Kelebihan | Ketebalan penyaduran |

| Electric Galvanized | Zink putih, zink putih putih, kromium trivalen | Lebih daripada 5 mikron |

| Penyaduran krom keras | Kekerasan tinggi | Lebih daripada 3 mikron |

digabungkan dengan penghantar roda , sistem pengendalian bahan moden boleh mencapai fleksi...

Baca lebih lanjutMemahami Penghantar Roller dalam Sistem Bersepadu Penghantar penggelek ialah komponen te...

Baca lebih lanjutMemahami Penghantar Penggelek Motor dalam Sistem Bersepadu Penghantar penggelek motor di...

Baca lebih lanjutMemahami Sistem Digabungkan dengan Belt Conveyor A penghantar tali pinggang jarang digu...

Baca lebih lanjutMemahami Penghantar Roller dan Peranannya dalam Pengendalian Bahan Penghantar penggelek ...

Baca lebih lanjutMembawa ketukangan ke masa depan.

No.60, Zhenhu North Road, Hudai Town, Daerah Binhu, Wuxi 214100, China

guijifeng@163.com

+86 139-2153-1116

+86-510-8558 1519/8558 1530

+86-510-8558 1520